Building and sustaining an efficient process requires a deep understanding of how well it is functioning as well as identifying bottlenecks hampering productivity. A step-by-step assessment can add valuable inputs towards eliminating waste, defects and variation.

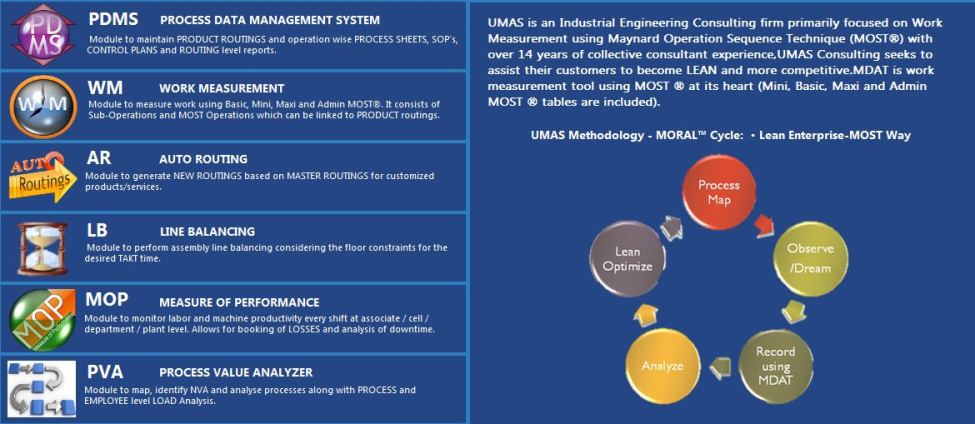

As a premier practitioner of MOST® (Maynard Operation Sequence Technique), UMAS uses its scientific and accurate tools like Process Data Management System (PDMS) to map out the process metrics in time and motion and uses it to create a lean, streamlined and efficient process.

PDMS™ is a pivotal step in the process improvement approach. UMAS deploys MDAT™ - Most Data Acquisition Tool – in the process of developing Routing data by Operation – A Process sheet which connects operation process parameters to Routings to generate SOP for operations which includes details like child parts, tools/gauges and required revisions.The Tool is highly effective in solving different Industrial Engineering problems as it correctly identifies the issues surrounding the routing or the flow of a process. It can be applied across all industry verticals.The MDAT™ allows for attaching of visual documentation such as photos and videos to showcase the step. This is highly useful for training operatives on the right workflow. The process sheet containing all relevant data connects routings to the mapped parameters for the operations, allowing for generation of SOP that include complex steps like child parts and revisions based on tools/gauges. It facilitates Operation wise FMEA and reveals information about activity wise postural analysis for MSD (Musculoskeletal Disorder) using REBA RULA Technique. Routing Level Content of Work and Analysis is available as well as Process Benchmarks and Comparisons are available.

With our expertise in process improvement we have leveraged MOST® on operational processes within dozens of organizations who have benefited from an average 30% improvement. We use a holistic perspective to suggest improvements in Layouts, Capacity Planning, Workforce Utilization and Corrected Routings.

The MDAT™ is a highly precise and dependable tool that gathers minute data on every step of the process - mapping the activity, the time taken and the physical movements involved

MDAT™ can be deployed flexibly allowing for use in production floors, back offices or service operations. Using Value Stream Mapping we can identify and solve several typical bottlenecks & identify Value Added Work Content

Our recommendations are holistic and use the data gathered to create a future state process that is not only free of waste or delays but also increases workforce engagement

As people who have delivered productivity benefits in a range of operations, UMAS consultants know how best to leverage MOST® and its systems for improved processes

UMAS PDMSTM allows you to qualitatively sequence work content in a process, streamlining & standardizing it for efficient workflow and improving workforce allocation as well. The end result is optimal use of people, space and equipment.

Create a shop floor that is scientifically designed for highest productivity.

Contact Us NowWe are an Industrial Engineering Consulting firm primarily focussed on scientific work measurement technique, providing our clients with problem - solving expertise to address problems of defects, waste and poor efficiencies in operations...

PDMSTM: Process Data Management

MOPTM: Measure Of Performance

PVATM: Process Value Analyzer

LBTM: Line Balancing

TDABCTM: Time-Driven Activity Based Costing

SCMTMSupply Chain Management