The competitive and always under pressure manufacturing environment of today requires that companies have operational processes that are efficient and highly productive. Being lean and continuously incorporating improvements is an essential factor for manufacturers to remain profitable and ahead of competition.

As the country’s premier practitioners of MOST® (Maynard Operation Sequence Technique) we use this scientific and accurate technique to identify improvement areas in your production floor. MOST® has a strong correlation with Lean, Six-Sigma and key Statistical tools, which when used together deliver significant transformation in process capability and productivity.

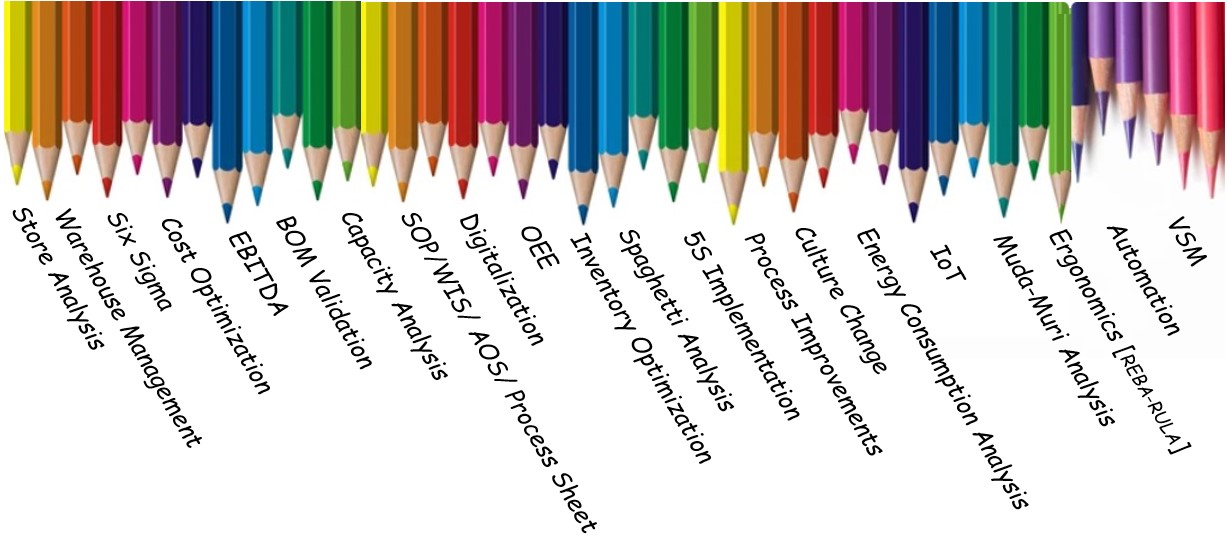

Our experienced consultants will work with you to carefully evaluate and map current processes using specialized tools and then carrying out in-depth analyses of activities and their timings to develop recommendations that will ultimately lead to optimization of your processes, minimization of waste & strain and overall improvement in quality.

Training on Basic, Mini, Maxi and Admin MOST®

Work Measurement using MOST®

Workforce Productivity Improvement

Continuous Monitoring of Productivity

Line Balancing

Capacity Analysis

Inventory Optimization

Facility Layout Planning – 3D Layouts, Animation

Method Study and Work Place Improvement using 5’S’

Manufacturing / Service Operations Simulation

Time-Driven Activity-Based Costing [TDABC]

2 - Bin Kanban System

KAIZEN

Poka - Yoke

Process Improvement Suggestions

Supply Chain Management [SCM]

Warehouse Management System

Ergonomics and Anthropometry

Single Minute Exchange of Die [SMED]

Value Addition (VA) / Non Value Addition (NVA) / Value Enabled (VE) Analysis

Advance Production Planning, Scheduling and Deployment [PPSD]

We have successfully completed numerous projects for a range of clients across various industries including: Manufacturing like Automotive, Electrical, Rubber and Services like IT, Airlines or Hospitality. Our work has typically resulted in productivity benefits of over 50+ percent for the organizations.

Using Work Measurement and Value Stream Mapping we create work standards that deliver clear direction and well-defined tasks, improving engagements.

Our grounds-up methodology focuses on providing recommendations that result in Improved Layouts, corrected routings and reduced delays & bottlenecks.

We build our recommendations using best practices from related techniques like Six Sigma to suggest you the most comprehensive optimization solution.

We use MOPTM calculations to measure workforce performance, helping in understanding overall effectiveness of a work center and managing capacity, etc.

You bank on having operations running at peak performance for sustained profitability. At UMAS, our aim is to qualitatively change the performance of your operations and the efficacy of your workforce. By implementing our optimizing recommendations, you will experience several benefits:

Leverage our expertise to see how you can bring these benefits to your organization.

Contact Us NowWe are an Industrial Engineering Consulting firm primarily focussed on scientific work measurement technique, providing our clients with problem - solving expertise to address problems of defects, waste and poor efficiencies in operations...

PDMSTM: Process Data Management

MOPTM: Measure Of Performance

PVATM: Process Value Analyzer

LBTM: Line Balancing

TDABCTM: Time-Driven Activity Based Costing

SCMTMSupply Chain Management