In a typical operational process, value adding steps, those that make it valuable to the customer or the business, often gets buried in wasteful activities that cost time and money. Businesses looking to boost productivity and improve flow/load balancing must seek to eliminate such bottlenecks.

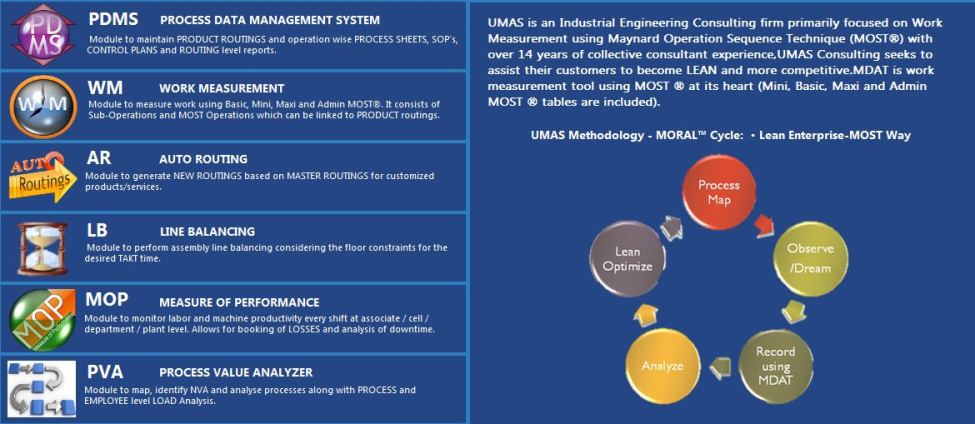

UMAS leverages a proprietary tool to carry out an in-depth analysis of a process, allowing the mapping of Value being added at each stage in office-based processes. The technique used in conjunction with MOST® operations, capturing critical information on the process.